Brief Introduction

DIAMONDWK CBN insert is a new type of cutting tool, which is sintered by cubic boron nitride and the special metal-ceramic composites in the ultra-high temperature and pressure. For its low compatibility with ferrous material, so it is mainly applied in ferrous materials machining processes.

Under the special temperature and pressure conditions, redesigning the bonding between particles from the microscopic level of the crystal surface and interface, DIAMONDWK inserts are better in heat resistance and wear resistance compared with other CBN inserts from home and abroad.

Product Size

|

Name (grade) of PCBN |

CBN content |

Hardness (HV or HK), GPa |

Application |

|

S1 |

90.00% |

4100-4300 |

With certain impact resistance and high wear resistance, it is suitable for continuous rough and semi- finish casting high speed steel, alloy cast iron and hardened steel machining whose hardness are above HRC55. |

|

S2 |

70.00% |

4000-4200 |

With better impact resistance and high wear resistance, it is suitable for light continuous semi-finishing and finishing machining for hardened steel and those which are hard for machining. |

|

S3 |

50.00% |

2700-2900 |

With high impact resistance and certain wear resistance, it is suitable for interrupted rough and semi-finishing machining for hardened steel and those which are hard for machining. |

|

S4 |

60.00% |

2900-3000 |

With better impact resistance and high wear resistance, it is suitable for interrupted roughing and semi-finishing machining for hardened steel, ductile cast iron and those which are hard for machining. |

|

S5 |

75.00% |

3300-3500 |

With higher impact resistance and better wear resistance, it is suitable for light continuous semi-finishing and finishing machining for hardened steel and those which are hard for machining. |

|

X2 |

85.00% |

3700-3900 |

With better impact resistance and higher wear resistance, it is suitable for continuous semi-finishing and finishing machining for alloy cast iron with high hardness, high-Ni-Cr cast iron and high chromium cast iron. |

|

X3 |

92.00% |

3900-4100 |

With better impact resistance and wear resistance, it is suitable for interrupted roughing and semi-finishing and finishing grey cast iron machining. |

|

X5 |

85.00% |

3500-3700 |

With better impact resistance and wear resistance, it is suitable for semi-finishing and finishing boron copper cast iron machining. |

|

Q |

Special formular |

Above 4200 |

Be mainly applied in components which are under complex conditions, and at the same time, which have high requirements for strength, toughness and wear resistance, such as bent axle, camshaft, cylinder liner and engine crankcase fot automobile, tractors, heavy duty machinery, internal combustion engine and etc, also be applied in mediun-pressure valve for general machinery. |

Production Process

![@LNJX`]X9@[SY8GJ9KAIRZC](https://www.diamondwk.com/Content/upload/2018332850/201810151504461392875.png)

|

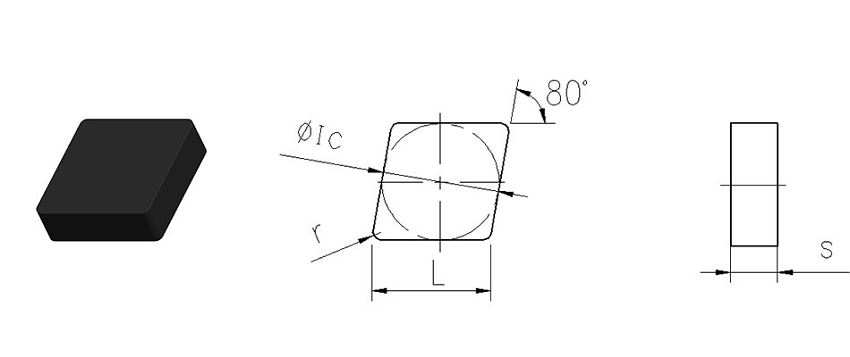

ISO |

Dimension |

Cutting Edge Form |

Grades | ||||||

|

ISO |

L |

φIC |

S |

r |

S1 |

S2 |

X2 |

X3 |

|

|

SNMN090404 |

9 |

9.525 |

4.76 |

0.4 |

T01020 T01025 T02020 S01020 S01025 S02020 S05020 S10020 |

|

|||

|

SNMN090408 |

9 |

9.525 |

4.76 |

0.8 |

|||||

|

SNMN090412 |

9 |

9.525 |

4.76 |

1.2 |

|||||

|

SNMN120404 |

12 |

12.7 |

4.76 |

0.4 |

|||||

|

SNMN120408 |

12 |

12.7 |

4.76 |

0.8 |

|||||

|

SNMN120412 |

12 |

12.7 |

4.76 |

1.2 |

|||||

|

SNMN150712 |

15 |

15.875 |

7.94 |

1.2 |

|||||

|

SNMN150716 |

15 |

15.875 |

7.94 |

1.6 |

|||||

|

SNMN201020 |

20 |

20 |

10 |

2.0 |

|||||

|

SNMN201024 |

20 |

20 |

10 |

2.4 |

|||||

|

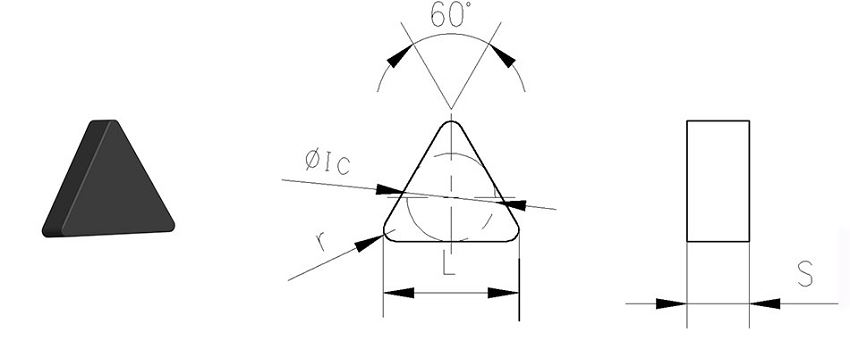

ISO |

Dimension |

Cutting Edge Form |

Grades | ||||||

|

ISO |

L |

φIC |

S |

r |

S1 |

S2 |

X2 |

X3 |

|

|

CNMN090404 |

9 |

9.525 |

4.76 |

0.4 |

T01020 T01025 T02020 S02025 S02030 |

|

|||

|

CNMN090408 |

9 |

9.525 |

4.76 |

0.8 |

|||||

|

CNMN090412 |

9 |

9.525 |

4.76 |

1.2 |

|||||

|

CNMN120404 |

12 |

12.7 |

4.76 |

0.4 |

|||||

|

CNMN120408 |

12 |

12.7 |

4.76 |

0.8 |

|||||

|

CNMN120412 |

12 |

12.7 |

4.76 |

1.2 |

|||||

![D78P4J935EOWG~T]%R$YEPF](https://www.diamondwk.com/Content/upload/2018332850/201810151508091857177.png)

|

ISO |

Dimension |

Cutting Edge Form |

Grades | ||||||

|

ISO |

L |

φIC |

S |

r |

S1 |

S2 |

X2 |

X3 |

|

|

RNMN090400 |

9 |

9.525 |

4.76 |

0 |

T01020 T01025 T02020 S02025 S02030 S05020 |

|

|||

|

RNMN120400 |

12 |

12.7 |

4.76 |

0 |

|||||

|

RNMN120700 |

12 |

12.7 |

7.94 |

0 |

|||||

|

RNMN150700 |

15 |

15.875 |

7.94 |

0 |

|||||

|

RNMN200700 |

20 |

20 |

7.94 |

0 |

|||||

|

RNMN201000 |

20 |

20 |

10 |

0 |

|||||

![`Y0XM2@Z74DG]IKHYJITBP0](https://www.diamondwk.com/Content/upload/2018332850/201810151511105249608.png)

|

ISO |

Dimension |

Cutting Edge Form |

Grades | ||||||

|

ISO |

L |

φIC |

S |

r |

S1 |

S2 |

X2 |

X3 |

|

|

DNUN110404 |

11 |

9.525 |

4.76 |

0.4 |

T01020 T02020 T02025 S01020 S02020 S02030 |

||||

|

DNUN110408 |

11 |

9.525 |

4.76 |

0.8 |

|||||

|

DNUN110412 |

11 |

9.525 |

4.76 |

1.2 |

|||||

|

DNUN150604 |

15 |

12.7 |

6.35 |

0.4 |

|||||

|

DNUN150608 |

15 |

12.7 |

6.35 |

0.8 |

|||||

|

DNUN150612 |

15 |

12.7 |

6.35 |

1.2 |

|||||

|

ISO |

Dimension |

Cutting Edge Form |

Grades | ||||||

|

ISO |

L |

φIC |

S |

r |

S1 |

S2 |

X2 |

X3 |

|

|

TNMN110404 |

11 |

6.35 |

4.76 |

0.4 |

T01020 T02020 S01020 S02020 |

|

|||

|

TNMN110408 |

11 |

6.35 |

4.76 |

0.8 |

|||||

|

TNMN110412 |

11 |

6.35 |

4.76 |

1.2 |

|||||

|

TNMN160404 |

16 |

9.525 |

4.76 |

0.4 |

|||||

|

TNMN160408 |

16 |

9.525 |

4.76 |

0.8 |

|||||

|

TNMN160412 |

16 |

9.525 |

4.76 |

1.2 |

|||||

Related Products