Wanke Company specializes in the production of Polycrystalline Diamond Compact, PCD wire drawing die blanks, PCD cutting tools blanks, and PCBN, etc..

DIAMONDWK keeps ahead in the superhard materials and related products area for its huge capacity after more than twenty years’ hard working in superhard industry.

DIAMONDWK keeps ahead in the superhard materials and related products area for its huge capacity after more than twenty years’ hard working in superhard industry.

Brief Introduction

Polycrystalline diamond compacts (PDC), which are composed of diamond and WC/Co substrate, and synthesized at the ultra-high pressure and high temperature conditions, are widely applied as the tooth of oil and gas drilling bit.

The surface of the polycrystalline diamond compact (PDC cutter) is polycrystalline diamond sintered from powders of different diamond sizes, which has a high hardness, high wear resistance, great thermal stability, and a long working life.

DIAMONDWK PDC cutters are widely used in oil and gas drilling.

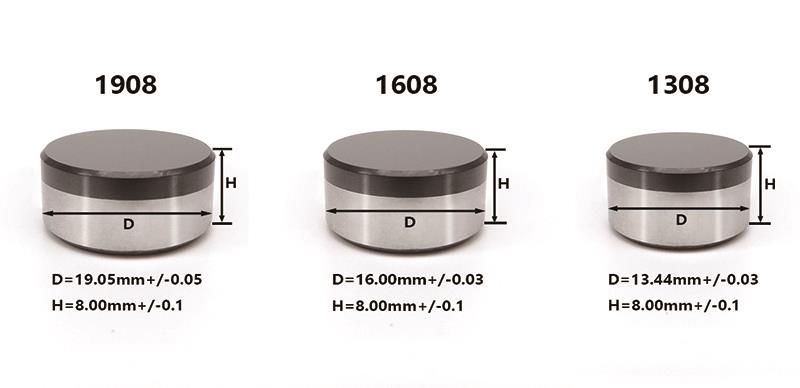

Product Size

|

Size |

Diameter (MM) |

Height (mm) |

PCD Thickness (mm) |

Diamond Chamfer(mm) |

Substrate Chamfer(mm) |

|

1308 |

13.44±0.03 |

8.00±0.10 |

2.30±0.20 |

0.30±0.10 |

0.5×45° |

|

1313 |

13.44±0.03 |

13.20±0.10 |

2.30±0.20 |

0.30±0.10 |

0.5×45° |

|

1608 |

15.88.16.00±0.03 |

8.00±0.10 |

2.30±0.20 |

0.30±0.10 |

0.5×45° |

|

1613 |

15.88.16.00±0.03 |

13.20±0.10 |

2.30±0.20 |

0.30±0.10 |

0.5×45° |

|

1908 |

19.05±0.05 |

8.00±0.10 |

2.30±0.20 |

0.30±0.10 |

0.5×45° |

|

1913 |

19.05±0.05 |

13.20±0.10 |

2.30±0.20 |

0.30±0.10 |

0.5×45° |

|

1916 |

19.05±0.05 |

16.31±0.10 |

2.30±0.20 |

0.30±0.10 |

0.5×45° |

Related Products